Wastewater Treatment

Wastewater Treatment

![[pics:title]](/static/upload/image/20221117/1668670583583995.jpg)

DESCRIPTION:

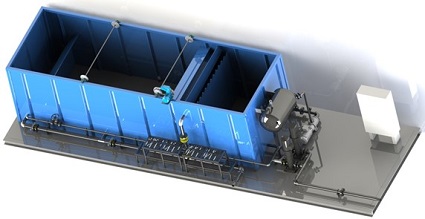

Industrial wastewater contains many kinds of substances, which pollute the environment seriously, and most of them contain toxic and harmful substances. The treatment of industrial wastewater needs to adopt targeted treatment processes according to the different water quality. The treated industrial wastewater can be reused or released to the environmental sewer or surface water. In order to meet the needs of the international market, SEPARATE equipment has developed an integrated municipal wastewater treatment system that meets the international market standards, meets container transportation, and has remote data monitoring.

MAIN INDUSTRIES:

The products are mainly used in the following markets:

food processing industry wastewater

pulp and paper industry wastewater

textile industry wastewater

oil&gas industry wastewater

Oily wastewater from ships

CORE PROCESS TECHNOLOGY:

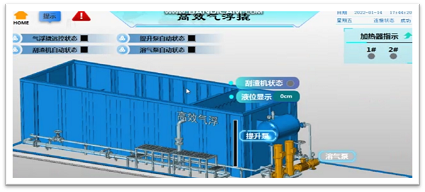

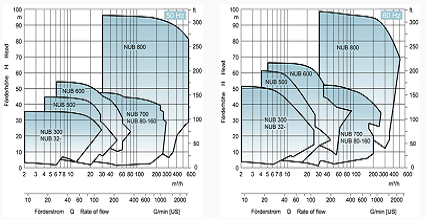

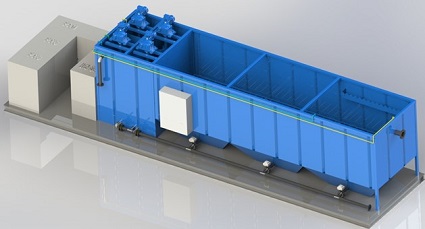

Super effective air flotation technology

The air flotation equipment using Germany EDUR original imported multiphase flow pump, in the process it can achieve a very perfect effect, when the liquid and air is sucked from the inlet of the pump, air in a highly dispersed state achieves a complete mix with liquid, the solubility of the liquid dissolved air can reach 100% saturation state, the air exists in the microbubble dispersion state in the liquid, the average diameter of the bubble ≤ 26 microns; Liquids with air content of up to 30% can be transported stably.

Compared with traditional air flotation system, it can save air compressor, pressure vessel, releaser, control system and valve, centrifugal pump, the system is greatly simplified and more reliable. Bubble liquid generated by multiphase flow pump enters the air flotation reaction tank, and microbubbles are attached to suspended solids particles as carriers. The difference in air and liquid density is used to float solids to the water surface to form scum. The scum scraping mechanism is used to scrape the scum to remove oil and suspended solids to achieve solid-liquid separation.

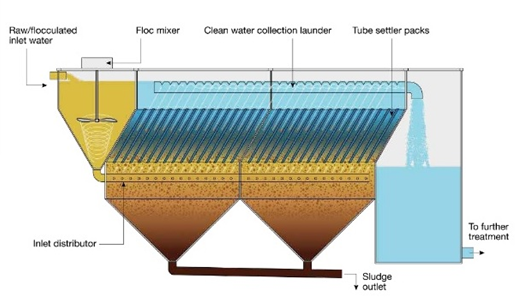

Multifunctional settlement technology

The multifunctional settler is a high efficient solid-liquid separation device that can obtain multiple effective areas per unit area by setting a number of thin plates in the sedimentation separation area. Based on the practice of "shallow tank theory", the floor area of the inclined plate sedimentation tank is reduced by 90% compared with the traditional sedimentation tank. The equipped mud scraper successfully solves the problem of unsmooth sludge discharge and improves the separation efficiency by more than 45%.

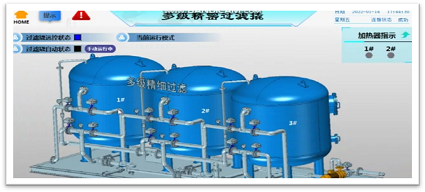

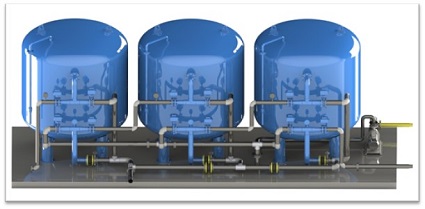

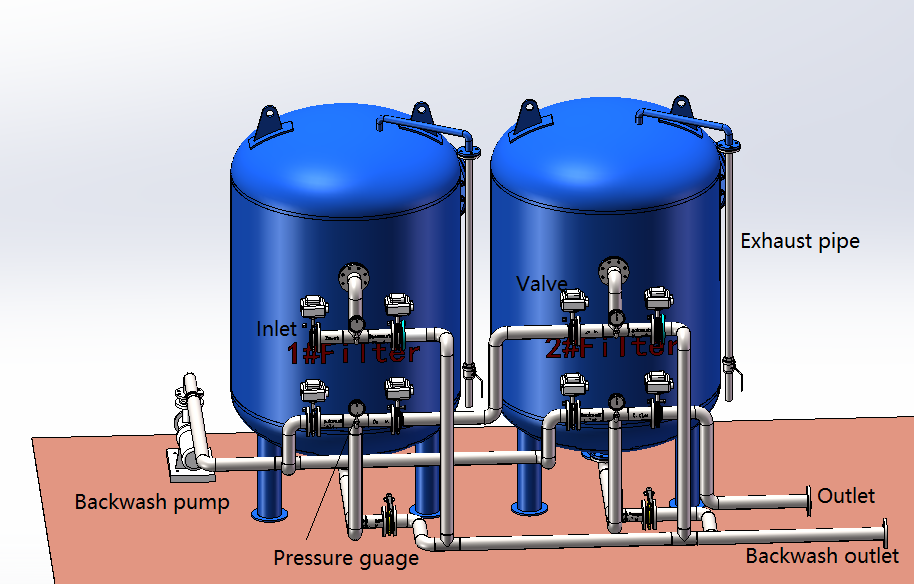

Full automatic multi-stage filtering technology

Multi media filter is a process that uses one or several filter media to filter water with high turbidity through granular or non granular materials with a certain thickness under a certain pressure, so as to effectively remove suspended impurities and make water clear. The commonly used filter media are quartz sand, anthracite, manganese sand, etc., which are mainly used for water treatment turbidity removal, softened water, pre pretreatment of pure water, etc. The turbidity of the effluent can be less than 5mg/l. The filtering system realizes automatic operation and monitoring, which can effectively prolong the service life of the filtering system and reduce personnel investment.

Remote control and cloud management system

Our company provide fully automatic control system to wastewater treatment plant, which makes it possible for a single person to operate the complete system. The control mode of centralized monitoring, operation and local operation in parallel reduces the number of on-site operators while ensuring convenience and safety. According to the requirements of informatization and intelligence, the remote control and monitoring system developed by our company can realize remote data monitoring and automatic data reporting of the processing station. It can be connected with the customer's big data platform according to the renewable demand.