Oil&Gas Field

Oil&Gas Field

![[pics:title]](/static/upload/image/20221117/1668670590648856.jpg)

MAIN SERVICES:

SEPARATE provide solution and equipment for

Solid control system /oil drilling mud treatment

Drilling Waste Management

Produced water & frac flowback fluid treatment

Oil sludge treatment

SOLID CONTROL:

Oilfield solids control system is mainly to control and separate the solids of petroleum drilling fluid, which can make the drilling fluid recycle, also called mud purification system.

It is suitable for the drilling process of 2000-7000 meters oil well. The oilfield solid control system is composed of 3 to 7 modular combined tanks; the bottom of the purification tank adopts a new type of cone bottom structure, and the mud mixing system is used at the edge to prevent sanding; the entire circulation system The tanks and tanks and warehouses can be separated and connected to meet the needs of drilling operations. The bottom valve of the suction manifold can be opened flexibly and sealed reliably after closing. The entire circulation system is equipped with 5-stage purification equipment, vibrating screens in supporting equipment, sand and desilter cleaners, vacuum degassers and agitators, etc. The use of new oil drilling mud purification systems reduces mud discharge and has obvious environmental protection Protective effects.

Equipped with weighted mixing device, priming device and chemical agent filling device. It is used to improve the physical and chemical properties of drilling fluid to meet the needs of drilling work.

The mud cleaner is the secondary and tertiary solid control equipment for drilling fluid. It combines a set of desanding cyclones, desilting cyclones and an underflow screen (mud shaker) into one. With small space and powerful functions, it is an ideal equipment for secondary and tertiary solids control of drilling fluids

The desander is a secondary solid control equipment for drilling fluid in drilling operations. It usually has 8", 10", and 12" cyclone groups, which are mainly used to separate solid phase particles with a particle size of 47-76 microns in drilling fluid. The desand cleaner is mainly composed of a vibrating screen, a cyclone, a diversion manifold, and an electric control system. The desander is used to separate solid particles that cannot be separated by the vibrating screen.

Solid control | ZJ10 | ZJ20 | ZJ30 | ZJ40 | ZJ50 | ZJ70 |

Mud tank(m³) | ≥80 | ≥160 | ≥165 | ≥180 | ≥200 | ≥270 |

Storage tank(m³) | X | X | ≥80 | ≥80 | ≥120 | ≥160 |

Shale shaker (m³/h) | ≥80 | ≥140 | ≥180 | ≥240 | ≥280 | ≥360 |

Degasser(m³/h) | X | √ | √ | 240 | 300 | 360 |

Desander(m³/h) | √ | ≥120 | ≥180 | ≥200 | ≥240 | ≥320 |

Desilter(m³/h) | √ | ≥120 | ≥180 | ≥200 | ≥240 | ≥320 |

Centrifuge(m³/h) | X | √ | √ | 40 | 50 | 50 |

High speed centrifuge(m³/h) | X | X | X | √ | 35 | 40 |

Mixer(m³/h) | ≥80 | ≥120 | ≥180 | ≥200 | ≥240 | ≥300 |

Shear pump(m³/h) | X | ≥100 | ≥120 | ≥120 | ≥120 | ≥120 |

Centrifugal pump(m³/h) | X | ≥100 | ≥150 | ≥180 | ≥200 | ≥240 |

WASTE MANAGEMENT:

Drilling waste treatment system is also known as non-falling mud system, non-falling cuttings system, non-falling cuttings system, and non-falling mud treatment system while drilling. According to the purpose, it is divided into: water-based mud non-floor system and oil-based mud non-floor system. Its main equipment includes: drying vibrating screen, cuttings dryer, drilling fluid centrifuge, screw conveyor, screw pump, etc. Our mud non-falling system can effectively control the moisture content (6%-15%) and oil content (2%-8%) of cuttings in drilling mud. SEPARATE has three sets of system configuration schemes:

Proposal 1

The system is mainly composed of a vibrating screen, a centrifuge and a tank, and is mainly used for the treatment of waste mud and tailing mud of drilling water-based mud. The advantage is that the treated mud can be recycled and reused, but the disadvantage is that the solid phase has a large water content after treatment

Proposal 2

The system is mainly composed of a dryer, a centrifuge and a tank, and is mainly used in the treatment of various drilling oil-based muds, water-based muds and tailings. After treatment, the solid phase contains oil and low water content

Proposal 3

The system is mainly composed of a filter press, a dosing device and a tank, and is mainly used in the treatment of various drilling water-based muds and tailings. Advantages Low water content in the solid phase after treatment, disadvantages: complicated process and large floor area

MORE DESIGNS

Frac Flowback & Oily Wastewater Treatment:

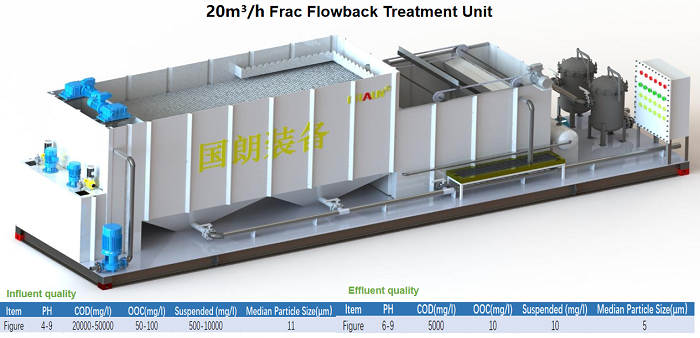

Fracturing is a common measure used for oil and gas production. Oilfield fracturing backflow fluid is generated during the process of production increase and backflow, and its composition is complex and variable, such as containing crude oil, polymers, water, sand, fungi, etc. It has the characteristics of complex composition, multiple types, high content, high viscosity, high emulsification degree, and high processing difficulty. Targeting the characteristics of fracturing flowback fluid, our company provides a complete set of treatment equipment and integrated solution design for fracturing backflow fluid, which is suitable for guanidine gum system fracturing backflow fluid, sliding system fracturing backflow fluid, clean fracturing backflow fluid system fracturing backflow fluid, oilfield wastewater, oilfield produced water, etc. generated during drilling and stimulation of oil wells, gas wells, and coalbed methane wells. The effluent standard meets the A2 reinjection standard (suspended solid content < 3mg/L, suspended particle diameter median < 2um, oil content < 5mg/L) or meets the fracturing fluid reuse water index.

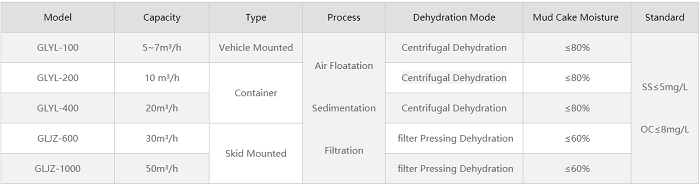

Models