Tunnel mud separation

Tunnel mud separation

![[pics:title]](/static/upload/image/20221117/1668670575537124.jpg)

DESCRIPTION:

Slurry treatment is the process of reducing, stabilizing and harmless treating mud.In the process of industrial wastewater treatment, river dredging, and (micro) tunneling construction, the sludge generated at the end of CRAUN efficient and environmentally friendly mud water treatment system needs to be further dehydrated and dried.

SEPARATE high-efficiency and environmentally friendly sludge treatment system consists of a high-frequency vibrating shale shaker, an integrated desander and desilter device, a dehydration centrifuge and a drying filter press. CRAUN stacked sludge dewatering scerwpress is widely used in municipal sewage treatment and industrial wastewater treatment.

MUD SEPARATION:

CRAUN separation technology is applied to the mud-water circulation system during construction, and the mud-water separation station can perfectly meet the needs of tunnel excavation technology. It continuously separates the slurry suspension from the solid particles in the slurry loop. The powerful combination of high G- force shakers and low tangential cyclone reduces the moisture content of the spoil and the solid content of the mud. The extremely fine particles remaining in the mud have an important influence on parameters such as tunneling speed and daily footage. Centrifugal separation technology can be used for further processing to prevent the mud density from increasing and affecting the tunnel boring machine's excavation efficiency.

CRAUN can separate particles of different sizes from the mud according to different construction needs, so as to realize the recycling of mud. It is mainly used in non-excavation mud purification, pipe jacking/shield tunnel mud circulation, diaphragm wall construction mud separation, pile foundation engineering mud treatment, etc.

MUD-WATER SEPARATION FUNCTION:

1. Provide the high-quality bentonite mud required for the tunneling construction of the shield machine to the airtight cabin of the excavation face;

2. Make the technical indicators such as the specific gravity and viscosity of the mud meet the requirements of forming a mud film and stabilizing the excavation surface in the highly permeable sand layer;

3. Transport the mixed mud formed by cutting soil and sand to the ground for separation and treatment, and then adjust and utilize the recovered mud;

4. Support and stabilize the excavation surface soil. The face of the shield can effectively support the front soil by means of the mud-water pressure and the front soil pressure to produce a mud-water balance effect;

5. Cool and lubricate the cutting equipment such as cutter head and cutter head;

6. According to the different requirements of the soil permeability coefficient, reasonably match the muddy water particle level.

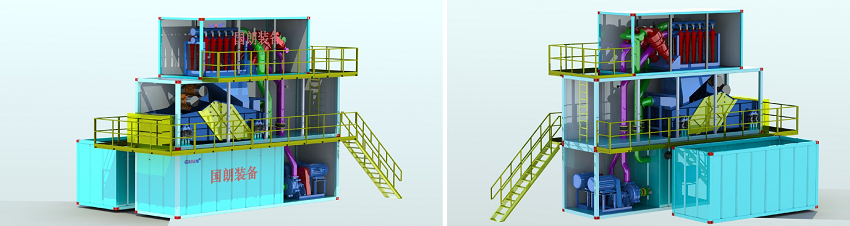

GSP SEPARATION SYSTEM:

GSP type mud-water separation system is suitable for the separation and circulation of mud in mud-water balanced pipe jacking, micro-shield tunneling, pile foundation engineering, and diaphragm wall construction. Its advantages lie in high separation accuracy, small footprint, and continuous and stable work, which is beneficial to improving hole formation. It plays an important role in improving efficiency, reducing construction cost and reducing construction risk.

DESIGN CONCEPT:

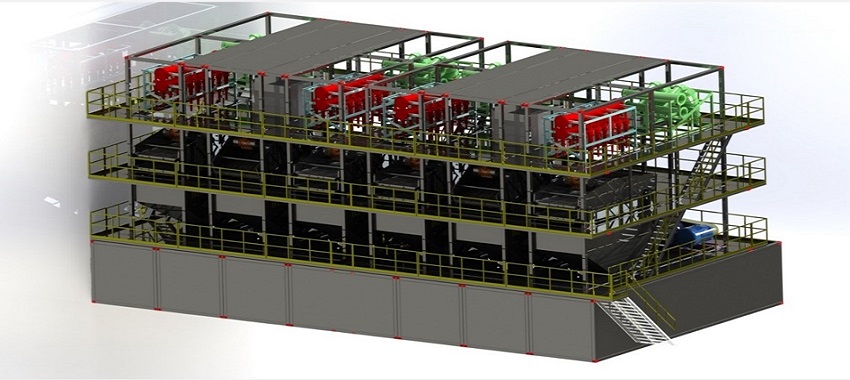

Modular, pre-assembled structure with small footprint, convenient and flexible assembly and disassembly, and rapid system expansion;

Efficient and powerful components with high excitation force and low cut point for high solids removal and good dewatering results;

The selection of wear-resistant materials and the design process after hydrodynamic analysis ensure the optimal purification effect of the equipment;

Designed according to the construction requirements of infrastructure projects, meeting the mud performance requirements of drilling machines.

MCS SEPARATION SYSTEM:

MCS series mud-water separation system is mainly suitable for ¢6m-¢13.5m mud-water balance shield machine, meeting the requirements of 650-5200m³/h mud circulation treatment. The MCS mud-water separation station can perfectly meet the needs of the tunneling process. It continuously separates the slurry suspension from the solid particles in the slurry loop. The powerful combination of high exciting force screening equipment and low tangential cyclone reduces the moisture content of the spoil and the solid content of the mud. The extremely fine particles remaining in the mud have an important influence on parameters such as tunneling speed and daily footage. Centrifugal separation technology can be used for further processing to prevent the mud density from increasing and affecting the tunnel boring machine's excavation efficiency.

HDD MUD SEPARATION: